As I mentioned in my last post, thanks to the generosity of Specialized, Chris Yu, and Cam Piper (both pictured above), I recently had the opportunity to spend a day in Morgan Hill, CA at Specialized's Win Tunnel facility. You're probably asking "How did THAT happen?" (something I asked myself repeatedly)...and well, it's a long story. I had met Chris Yu a few years back when I had the opportunity to observe the wind tunnel testing of my friend and professional triathlete, Jordan Rapp. At the time, Specialized had recently opened their "Win Tunnel" facility and I had a great time watching the proceedings and trying not to be too annoying in peppering Chris and Mark Cote with questions. Since that time, Chris and I had "conversed" on various forums, and even swapped a few emails.

Earlier this year, Chris had sent me an email asking if I was interested in participating in one of their videos that they occasionally produce. I jumped at the opportunity and said "Sure!" and we planned on doing something in the July/August time frame. Well...one thing led to another, and the planned purpose of the video was changed...and then it turned out the video team wasn't going to be available on the dates we had planned. No worries though. As Chris explained to me, the tunnel time was already blocked out, and it turns out that like most forward thinking companies based in the SF Bay area (i.e. Google, Apple, etc.) Specialized allows their engineers time to "play", or pursue subjects that may not have an immediate application...on the thought that this "playtime" may spark some unexpected innovation. Chris told me we could brainstorm and come up with some things to look at, and like most tests, we'll most likely come up with some answers, but also some good additional questions to pursue. Sweet. How could I say no?

Due to the VERY large amount of data collected, what you'll see here in Part 1 is mostly the results of the morning of testing on that day in the Specialized Win Tunnel. I came up with the idea of trying a host of wheel and tire combinations, and then following it up with some of those same wheels and tires in bare bike tests...and then finally, I was hoping to get into the tunnel on a bike myself for a few runs. Shown below are the wheel/tire results. Part 2 (coming later) will show the remainder of the data. The idea was to see what sort of info could be gleaned about how wheel and tire combos are affected by the tire mounted (especially width) and if the differences observed "carried through" to both bare bike testing and testing with a rider. It was an "ad hoc" plan and group of equipment, but I figured at a minimum I would be getting a crash course in wind tunnel testing and the difficulties of doing so.

What you see above is the test matrix I put together for the wheel and tire testing. The wheels listed in the column on the left are the ones I would had available to me, and run the gamut from shallow to very deep. Across the top are listed the tires. Knowing that there was a limited time for the wheel/tire runs, I decided to go for a mix of tires on the wheels, with the one I was most interested in seeing was the one in the first column, the new S-Works Turbo 22C model. The greyed cells are the combinations tested, with the number in front of the hyphen the order in which they were to be tested. I wanted to make sure we weren't wasting time waiting for a tire to be swapped for a run. The number after the hyphen is the measured width, as mounted.

So, let's get to the data...but, before we do that, I want to point out how difficult it is to get "clean" data using equipment this sensitive. Seemingly small things can throw some of the results off...which is why it's good to have guys with tons of experience running the show. For example, when we ran the first runs using a "known" wheel/tire combo (the Roval CLX64 with S-Works Turbo 22C), Cam immediately noticed that the positive yaw values seemed "off"...and it was traced to simply an end cap on the wheel fixture not being fully seated. Anyway, after 11 runs, here's how the data looked as a whole.

The big takeaway there is that the Roval CLX64 w/S-Works Turbo 22C truly is the "benchmark" for this grouping of wheels and tires tested. The Jet 6+, also with the S-Works Turbo 22C tire, basically matches it, although at the positive 15 deg point there appears to be an asymmetry (which should probably be investigated - Is it the wheel? Fixture? Tire?).

Looking closer at just the Jet 6+ runs, here's how they looked:

Another thing to note about the above data is that the Turbo Cotton 24C tire tested was my own personal tire with ~700 miles of front wheel use at that point. As can be seen, the wider 24C tire gives up some drag, not only at zero yaw, but especially so at the higher yaw angles. However, don't forget that the Turbo Cotton tires have VERY good Crr properties, so when we look at this data in an "overall speed" context, the differences may not be as large. THAT analysis will be done in a later blog post.

Another wheel tested was my personal Zipp 101 wheel. For this one, I wanted to see the effects of tire width for such a shallow wheel, so the comparison was between the S-Works Turbo tires in both the 22C and 24C sizes. As you can see, the 2mm wider tires results in a fairly fixed offset across the range of yaw angles tested:

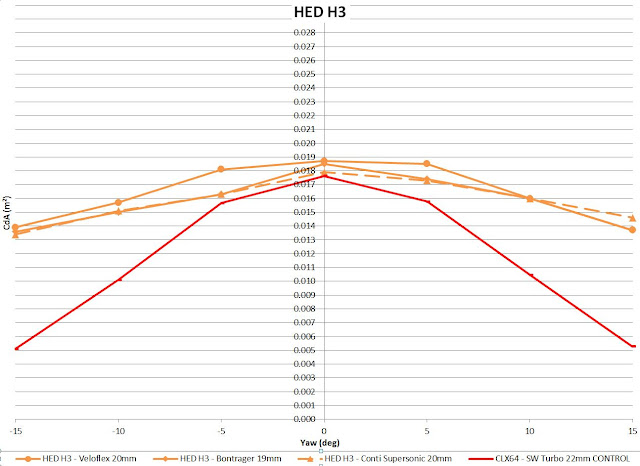

One of the things I wanted to check out in the wheel/tire testing was how well the venerable Specialized Trispoke/Hed H3 wheel performs vs. more modern wheels...plus, I wanted to see how well it worked with a VERY narrow tire, like it was designed around. As such, I took a brand new "out of print" Bontrager Aero TT 19C tire and compared it to the 20C Veloflex Record (that the wheel owner used as a tire) and also a 20C Continental Supersonic. As can be seen below, as compared to the Roval "benchmark", the older wheel leaves a bit to be desired, especially at yaw angles above 5 degrees. To be fair, this data doesn't include "power to rotate", which some claim can be a significant advantage for the Trispoke/H3. In any case, I think it's fair to say that of the tires tried, the 20C Continental Supersonic is probably the best combination of aerodynamics and Crr for that particular wheel.

Lastly, we looked at my personal Flo 90 front wheel, comparing the aero performance between a Continental Attack 22C, a Continental SuperSonic 23C, and an S-Works Turbo 22C tire. The surprising result there (for me, at least) was how well the SuperSonic tire performed out to 10 degrees of yaw as compared to the other slightly narrower tires. Combine that aero performance with the excellent Crr of that tire, and it looks to be a tough combo to beat as a front wheel application (I'll have more on the aero+Crr combos in a later blog post). It's also important to note how well the Roval CLX64 wheel performed vs. a wheel 26mm deeper!

That's about it for now for this blog post. There's a ton of data I'd like to go through, and I figured it was high time I started sharing some of this stuff. I wanted to throw this stuff out there first to generate discussion. I'll have more analysis later.

For those interested, the entire data set can be found in this spreadsheet here: Wheel Aero Data

What happened with the CLX64 test in runs 57-63? Much lower values than the other runs for that combo? In fact, of 3 runs with new tyre it looks like a lot of variation?

ReplyDeleteThanks for making spreadsheet available so I can play with data.

That was the first run with the control combo in the afternoon, and it's within .001 of the other, later afternoon run...so those 2 are consistent. The "control" values plotted above are the average of all 3 runs.

ReplyDeleteAbout all I can think of is that there may be some un-modeled environmental variation in the data acquisition? That ended up being quite a hot day in Morgan Hill...I went on the lunch ride with Chris and Cam and I'm pretty sure we went through some spots that were in the triple-digits (Fahrenheit).

I knew you, for one, would appreciate the spreadsheet :-)

Oops...I mis-wrote above. Runs 57-63 were in the morning, not the afternoon. But, it shows that between those morning runs and the afternoon runs the agreement was tight. The first runs with the new tire (22-28) perhaps show some sort of "out of the box new tire" effect? Like I said...more questions than answers most times ;-)

DeleteThanks Tom. Great work!

ReplyDeleteSo are runs from 85 on a later session? Keen to see the other data you've mentioned :-)

ReplyDeleteAt my mass and on the surfaces I race it is disappointing that I always have to go for CRR taking priority (as do most riders if they've paid attention to us...) and sacrificing aero. Rationality just isn't as cool as having the most aero set up/

Yes. Runs 85 on where after an ~1.5-2 hour break for a ride and lunch, which is why the last run of the morning (Flo90 w/SWT 22)was repeated when we started back up again.

DeleteTom, I really can't thank you enough for this information, and for sharing it. This is spectacular. Since you didn't test the GP400s2, can you surmise anything based on previous testing efforts and coast-down tests?

ReplyDeleteIf I'm reading that right, the aerodynamic performance difference at 10 degree yaw across the range of wheel/tyre combos tested is approx 1 second per km, with adjustments for Crr variation to be layered on top.

ReplyDeleteSounds about right...

DeleteEagerly awaiting part two. I am really curious to see the numbers with Crr and aero data combined for the Specialized tires.

ReplyDeleteThere was also some talk that Spec changed to a lower TPI casing on the "regular" S-Works turbo tires (from 220 to 120tpi maybe?) and that would lead to the S-Works Cottons to be even faster-er in comparison.

Top stuff! Will be interesting how the new 2016 tyres with roll rr claims (eg. Zippy, vittoria graphene etc ) fair in the future

ReplyDeleteTom, really glad to see you getting some time in the wind tunnel to get some aero data to complement your great work on rolling resistance. Be interested to see what conclusions you reach when you combine the contributions of each.

ReplyDeleteMy readers are always asking if they can put wider tires (typically 25C) on their rims to improve comfort and rolling resistance. I always tell them you need to keep the pressure the same or not too much lower in the wider tire in order to improve rolling resistance but you'll probably offset those RR gains with aero losses, especially if the mounted/inflated tire width greatly (>1mm or so) exceeds the rim width, which it will be for a 25C tire with most any rim that isn't 26 or 27mm wide at the outer edge of the brake track. I ran several scenarios on rims and tires of different widths to show the amount of overlap and it can get quite large (see scenarios 1-6 here: http://intheknowcycling.com/2015/05/28/best-road-bike-tires/#Design).

Of course, the relative benefits of better tire aerodynamics and reduced rolling resistance depends on whether you are riding in the wind most of the time like a TT/Triathon or solo road cyclist (increases importance of aerodynamics) or you are drafting others in road race or doing group riding (increase importance of rolling resistance).

I wonder if your aero testing begins to quantify some of the effect of the width difference between the tire and rim at the outside edge of the brake track in aero performance? While only the tests on the Zipp rim test the same model tire at two different widths, there are considerable tire-rim width deltas with some of the different tires you ran on each rim. Using rim width measurements from Greg Kopecky, formerly at slowtwitch and wheel co data for the old Zipp and new Spesh wheels along with your mounted/inflated widths, I charted the tire-rim width deltas for the combinations you tested. It looks as follows:

-Zipp 101, SWT 22 Delta = -0.2mm (tire narrower than rim), SWT 24 Delta = +1.0mm (tire wider than rim

-Jet 6+, SWT 22 -0.5, TC 24 +1.7

-CLX 64, SWT 22 (old tire) -0.9, SWT 22 (new tire) -0.3

-FLO 90 SWT 22 -0.7, CSS 23 +0.4, CA22 -0.1

-H3 CSS 20 +0.8, VFR 20 +1.9, BATT19 ) +0.1

Any thoughts on how much of the aero performance difference is due to tire model choice vs tire-rim width deltas?

Best,

Steve

Hi Steve,

DeleteI'm glad you're enjoying the data. Yeah...there's a lot of "interactions" going on not only with tire model but also mounted width. That's one of those things that people seem to forget with the new wider rim models...the mounted width is going to be MUCH wider than the stated size, and that CAN have aero drag effects.

It's funny...but Chris Yu pointed out to me that nowhere on the new 22C S-Works turbo tire does is say "22" except for what's molded into the sidewall. The label itself says something like "24mm wide when mounted on a Roval CLX64 wheel"...and he insisted on that labeling due to people thinking the tire would be too narrow for use on a wheel.

There's going to be a follow on blog post with some excellent data that Cam Piper took a week after my visit. Aero data from all sizes of S-Works Turbo and Turbo Cotton on the CLX64 wheel :-)

Tom: Any insight if the S-Works Turbo Tubular Allround2 will roll as well as the Turbo Cottons? I'm looking for a tubie to replace my Schwalbe Ironman (butyl) on my Stinger disc. Flat protection and compound seem to be the same but the casing is different as per Spec's site.

ReplyDeleteHi Tom, great post! I was hoping to find out some details about the specialized facility where you performed drag measurements. Are they obtained using a force transducer? Also, was the wheel rotation driven by a motor or just allowed to rotate freely, and were the arms which hold the wheel in place designed with an aerodynamic profile to limit interference with drag measurements? Thanks, I'm designing a wheel test stand for use in measuring drag on racing wheels in a wind tunnel right now so any additional insight into this setup would be great.

ReplyDeleteHi Robert. The entire round platform you see in the picture at the top is a load cell to measure the aero drag forces. The wheel rotation is driven by a motor through a drum so that the wheel speed matches the wind speed. The "struts" are made from aero-section bar and are of a shape that stalls at a very high angle of attack, and are spaced widely apart. That is done to minimize interactions with the test articles. I hope that helps.

DeleteYour blog is very useful, I am truly to this blog which is specially for bikes, I really appreciate your blog.

ReplyDeletebiker

This is a phenomenal source of information. Thanks so much. I heard of this on the excellent Time Trial Podcast.

ReplyDelete