*edit 18Feb2020: There's a late-breaking addition to the list after I recently completed a test on the new Continental Terra Speed. See the list below and in the spreadsheet

OK...yeah, I know...it's been awhile since I wrote something here :-)

But, it's a new year (relatively speaking) and I've got some stuff I'd like to finally share. So, below is my first go at presenting hard surface rolling resistance data on tires intended for mixed-surface riding, A.K.A "gravel riding". I'm sure I'll be opening myself up to criticism from certain corners of the interwebs for looking at this, but I'll discuss below some of my reasoning on the subject and try to put the information into the proper (usable) context.

So, without further ado, here's a quick list of what I've tested so far, in descending order of Crr (full spreadsheet is located at the link to the right, or here):

TIRE CRR POWER (pair @30kph)

- Continental GP5000S 700x23c .0029 20W

- Specialized Turbo Cotton 700x28c .0031 21W

- Continental GP4000S 700x23c (control) .0035 25W

- Challenge Strada Bianca Pro 700x30c .0036 25W

- Compass Snoqualmie Pass EL 700x44c .0036 25W

- Challenge Strada Bianca Pro 700x36c .0038 27W

- Challenge Gravel Grinder Pro 700x36c .0041 29W

- Continental Terra Speed 700x40C .0043 30W*

- Compass Snoqualmie Pass 700x44c .0043 30W

- Panaracer Pari Moto 650Bx48c .0047 33W

- Challenge Gravel Grinder Race 700x42c .0047 33W

- Compass Bon Jon Pass 700x35c .0048 33W

- Challenge Gravel Grinder TLR 700x42c .0050 34W

- Panaracer Gravel King SK 700x32c .0051 35W

- Challenge Gravel Grinder TLR 700x38c .0051 35W

- Compass Steilacoom EL 700x38c .0056 39W

- WTB Byway 650Bx47 .0056 39W

- Challenge Gravel Grinder Race 700x38c .0057 40W

- Vittoria Terreno Dry 700x40c .0057 40W

Explanation:

Before diving into the actual results, it would be good to review a few notes about some of the test conditions and how the results are reported:

- The tires listed above (unless otherwise noted) have been tested at a pressure predicted to correspond with a tire "drop" (i.e. deflection under load) of 15% of the inflated casing height. There will be more on how that pressure is calculated below. The reason for doing so is that the tires in this category can vary in size by quite a bit, and it makes sense to compare their performance in a more "apples to apples" condition than with a fixed pressure (as I have done previously with road tires of similar size to each other).

- The power for a pair of tires is shown compared at 30kph, unlike the previous reporting for road tires at 40kph. This is to account for the generally lower average speeds encountered in mixed-surface riding. The spreadsheet reports values for 20, 30, and 40kph instead of the road spreadsheet reporting of 30, 40, and 50kph

- The top 3 tires listed are basically road tires. The Continental GP5000, although a 23C tire is listed mostly because I haven't shown a result for that yet (and some information linked to below indicates that the performance of the larger sizes is basically identical when run at Berto pressure). The GP4000S is just shown as a "control" and comparison to my previous road only results (still linked at the right). Lastly, the 28C Specialized Turbo Cotton is also another road tire I haven't shown results for in the past...but, in this case, I consider it to be the first of tires I would consider for "light gravel" use (and have used it as such). On rims of 20-21mm internal width, those tires measure nearly 29mm wide.

Discussion of Berto Pressure calculations:

Quite a long time ago, after discussing the subject with tire engineers, Frank Berto took on the task of measuring a range of tire sizes to determine the pressure required to result in a 15% deflection of the tire casing for a given load. The assumption was that this deflection point resulted in a consistent performance for a given tire size and load...and, if anything, was at least a good "starting point" for determining a preferred pressure. The results of those tests are shown in the chart by Berto above.

Because I wanted to use the charts for a wider range of tires and for sizes in between the shown lines for tire sizes, I decided to see if I could come up with a "universal" Berto pressure equation. To do so, I calculated the slope and intercept dependencies on tire size and wheel load. This resulted in a "pressure intercept" and "pressure slope" for each tire size curve. I then plotted these intercepts and slopes versus tire size in order to come up with a curve fit for each (and they were surprisingly linear). This exercise resulted in a "universal equation" to solve for pressure for any size and load. Now it's not necessarily predictive of actual pressures one would run (since that can be highly surface dependent) but it's a way to "normalize" for comparison purposes. That equation is embedded in the spreadsheet.

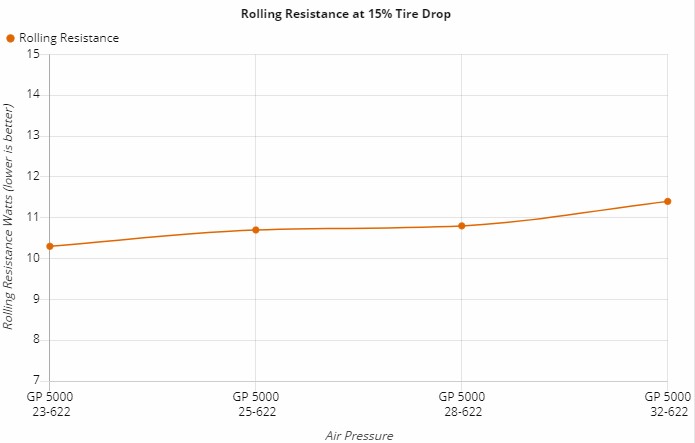

As an example, BicycleRollingResistance.com did a comparison of 4 different sizes of the Contintental GP5000 tires: https://www.bicyclerollingresistance.com/specials/grand-prix-5000-comparison , and in an interesting comparison there, the rolling resistance measured for all 4 sizes was within 1W when "normalized" to a measured 15% tire deflection. Perhaps ol' Frank was on to something ;-)

Because I wanted to use the charts for a wider range of tires and for sizes in between the shown lines for tire sizes, I decided to see if I could come up with a "universal" Berto pressure equation. To do so, I calculated the slope and intercept dependencies on tire size and wheel load. This resulted in a "pressure intercept" and "pressure slope" for each tire size curve. I then plotted these intercepts and slopes versus tire size in order to come up with a curve fit for each (and they were surprisingly linear). This exercise resulted in a "universal equation" to solve for pressure for any size and load. Now it's not necessarily predictive of actual pressures one would run (since that can be highly surface dependent) but it's a way to "normalize" for comparison purposes. That equation is embedded in the spreadsheet.

As an example, BicycleRollingResistance.com did a comparison of 4 different sizes of the Contintental GP5000 tires: https://www.bicyclerollingresistance.com/specials/grand-prix-5000-comparison , and in an interesting comparison there, the rolling resistance measured for all 4 sizes was within 1W when "normalized" to a measured 15% tire deflection. Perhaps ol' Frank was on to something ;-)

Anyway...I think I'll just throw this info out there for now to hopefully stimulate some discussion, and will probably go into further depth on the subject in future blog posts (I promise!)

So, not a fan of any Schwalbe tires I guess? Jk, but unfortunately for me, I only have three of those tires (Byway, GP4000 and 5000). I actually think the Byway has the potential to be a much faster tire, but the center rubber is REALLY thick. Good for punctures, long lasting, but no faster than an mtb tire even though the center is slick. I'm holding out hope that Conti keeps making bigger versions of the GP5000. Like 700x45mm.

ReplyDeleteHi Chad,

DeleteWhen I was first working out the protocol, I tested the G-One All-Around 700x38C tire...unfortunately, I had passed those along to a friend before realizing a problem with that initial testing (I wasn't measuring the wheel load correctly...and discovered that with my "control" tire run) and so I wasn't able to retest them later after I had corrected the problem.

That said, based on inference to similar tires tested at the same time using that incorrect method, I would expect that one to slot in right above the Bon Jon Pass, and tied with the Gravel Grinder Race 42C tire...but, without doing the real test, it's basically an educated guess

...and yeah, I was a bit disappointed in the Byway performance based on the reports of it being a "fast" tire. My on-road impression of them was that they were quite a bit lossy too (like riding through sand), which made me realize that most folks probably equate "quiet on pavement" with "fast" in this realm, so ANYTHING mostly slick HAS to be fast. It doesn't quite work that way though :-/

DeleteI did some side by side comparisons between a G-One Allround (38mm, but fairly worn down in the middle), G-One Speed (2.0), Conti Raceking protection (2.2), WTB Resolute (42mm) with a GP4000 as a control and was surprised how little variance there was in that group of tires. Now, those are all what I would consider decent rolling tires so I did not expect to find any dogs, but the variation from the road GP4000 to the mtb Raceking was only about 5-7 seconds over a five-minute climbing course.

ReplyDeleteI don't have a 650b rear wheel (my all-road bike is a 650 front/700 rear bike) so the only comparison I have there was a Byway vs a Schwalbe Thunderburt on the front, but those two were a dead heat after multiple runs. I was surprised and so I investigated further and that was when I measured the Byways center tread and it was like 3+mms. The TB has much less rubber down the center. WTB could probably make a much 'racier' version of the Byway by reducing the center tread in half because the Byway casing seems really flexible similar to the TB. I'm sure puncture protection and really, really long life are more appealing to most folks, so I don't suppose they feel the need to change it.

Tom, great to see a post from you again and good to see it on this topic. Do you have an interest in testing more gravel tires? If so, send me an email and we can discuss getting you others to test. Cheers, Steve

ReplyDeleteHello Tom, I am very interested on how you determined the 15% drop. Was it calculated using pressure, diameter, etc. e.g. casing tension/hoop stress methods? I am an amateur researcher working with vibration damping in wheelchairs and understanding how this is correctly done would be a great help.

ReplyDeleteHi, as mentioned in the article, I utilized the data taken by Frank Berto and available here: https://campusebikes.com/documents/Tireinflation.pdf , and also if you search the Bicycle Quarterly blog, I think there's a clearer image. I took his data and then "reverse engineered" an empirical fit. Does that make sense? I also found an algorithm online that apparently does the same thing based on casing tension (hoop stress) and compared it to the empirical Berto equation, and they are quite close. I hope that helps.

DeleteI was going to suggest investigating tire pressures based on casing tension, but it looks like you have already done that. I have wondered though if there is a way to quantify "appropriate tire pressure" due to tire casing stiffness. CX racers like to say that the handmade supple casing tubulars can be run a psi or two higher than vulcanized "stiffer" tubulars or clinchers, not sure how this would translate to Crr differences on rough surfaces though.

DeleteYes that helps, thanks Tom.

ReplyDeleteSo, is it a safe assumption that gp5000 in 32mm are 7w faster than strada bianca pro 36 at the right pressure, since the gp5000 23mm is? I'm using latex tubes is the strada bianca pro. Mixed surface for me is about half pavement, mostly dirt roads, a little bit of gravel.

ReplyDeleteI'm thinking more like in the 5-6W per pair range at 30 kph. That's what I was trying get across with that final plot from BRR showing the measured Crr at 15% drop across the GP5K size range. I've got a pair of 32s I'm running on my road bike now, but I didn't bother to roller test one prior to mounting them...too lazy, I guess ;-)

DeleteI'm glad you’ve done these tests and I have offered to provide you additional tires so that you can do more and we have more results to compare (no response to date).

ReplyDeleteThat said, it appears your tests of gravel tire rolling resistance are only a starting point for comparing road tires with gravel tires used on paved and hard pack dirt surfaces but perhaps not as realistic or translatable to gravel surfaces.

Why? A few reasons.

1) These tests are done with a very similar drum to the one you use to simulate road surfaces rather than one that would simulate dirt or gravel ones. It I read your spreadsheet correctly, it actually looks like you’ve used one with a smooth-to-rough factor of 1.5 for the road tire tests but only 1.2 for his gravel ones. The only tire you’ve tested on both drums come out with almost identical results (despite minor width and pressure differences). Gravel tires, of course, are designed for dirt and gravel surfaces so a rougher drum (or a different protocol) might be more useful.

2) You use latex tubes in tubeless tires with the exception of the 650B tires. Again, this is your road protocol and allows a comparison to road tires but I wouldn't think many riders (or any other than perhaps elite racers on hardpack, class 1 type dirt surfaces) would use a latex tube in a tubeless gravel tire. The tube would likely add more rolling resistance over a rough surface than a tire with no tube at all and likely pinch flat at the low tire pressures run by in gravel tires.

3) Finally, you use the Berto pressure calculation approach to normalize tire pressure at 15% deflection regardless of tire volume. That is a good way to do it, again for road tires, but it results in tire pressures that are far higher than you'd inflate them on gravel, in some cases as much as 20psi higher. Rolling resistance tests on road tires shows that rolling resistance differences aren't directly related to pressure. With semi-slick and small knob gravel tires having a variety of knob sizes, heights, spacing etc. as you go from the tire's center out to the shoulders, a less pressured tire would likely engage more of its surface with the road/drum and different knobs than would a more pressured one where less of the tire would be rolling against the surface.

Again, what you’ve done is a start and it's interesting and I'd like to see more but perhaps with a modified, more gravel-specific protocol. You pioneered road tire rolling resistance testing and it would be great to see you do the same with gravel tires. Thank you.

Hi Steve,

DeleteYeah...sorry for the lack of the reply, I actually haven't been checking this here for a bit. As far as testing a bunch of other tires, I'm going to have to say "not right now"...

To address your points:

1.) My intent with this testing was to actually concentrate MORE on the hard surface performance of these tires, since for this use case, it's been my experience that it's in those conditions that the casing construction and compound is more noticeably. I've long known from MTB'ing that more and bigger knobs are better in the really loose stuff, but also that those features tend to make a tire slower on hard surfaces. And casing flexibility differences are less noticeable off-road, since once the surface becomes softer, it's really all about how low of a pressure can you handle, for both grip and speed. For example, this is why CX racers love tubulars. Due to the artificial tire width constraint, they need to run super low pressures, and tubulars are less likely to roll off, burp, or pinch in that condition...when in reality, if they could run wider tires, tubulars wouldn't be necessary.

As far as "rougher drums" go...I've investigated this quite a bit, and realized that adding "roughness" to the drum doesn't really get you any more information, besides adding a fixed offset to the power requirement, so I don't really see the utility in that.

2. Yes, I use latex tubes in the tests. My tests, and tests by others show that a latex tube doesn't add any measurable Crr. So, for the sake of making it easier to test, I simply use appropriately sized latex tubes instead of messing around with sealant between each run.

3. I find the Berto pressure that's calculated is what would be appropriate for a tire that would ONLY be used on a perfectly smooth surface (like this test). I've also found, and seen data on, that when reducing the pressure in a tire for the expected conditions, the % differences between tires stays ~the same at their "ideal" pressures for that surface, so the rank order will stay approximately the same.

Thanks for the questions, and I hope I answered them to your satisfaction. If not, just ask away again :-)

Tom, Thanks for your response. Good to know the rationale behind why you did the tests on the surface and at the pressure you did.

DeleteCoincidentally, Tour Magazin just published tests of a dozen gravel tires, essentially a slick or lightly treaded center tire and a knobby tire from each of a half dozen leading brands. As you probably know, they do pendulum tests and did them on a road surface at 4, 3, and 2 bar and then on a gravel surface at 2 bar. A quick review of the results suggests a linearity and rather consistent percentage delta in rolling resistance as they went from higher to lower pressure on the road surfaces and then gravel, in most cases. Would have liked to have seen different types of "gravel" since there are several classifications from hard packed dirt to loose, deep gravel that we ride but their results confirm, at least directionally, what I interpret in your answer as your assumption/hypothesis/experience that you can project the differences on gravel surfaces from rolling resistant tests on hard surfaces.

Anyway, you might want to check it out. https://digital.tour-magazin.de/de/profiles/e983d8ae01f3-tour-browserclient/editions/tour-5-2020/pages/page/82

Cheers

How are the GP5k 32mm tires working out for you? I'm looking at those or the 35mm Terra Speeds or 35/38mm Rene Herse for a tire that could do faster-than-gravel speeds on road rides and still handle most of the gravel/dirt roads near me.

ReplyDeleteHi Binx, so far, so good! Not a single issue with them yet.

DeleteThanks for sharing. I have been going through your posts and have been enjoying all the wonderful information I'm getting from each one. Have a great day and hope all is well.

ReplyDeleteClassic Body Worx

I'm completely new to bikes. I bought a 1993 Rockhopper that I want to use mostly on pavement with the very occasional hard dirt trails. Any tire suggestions? I've been watching videos and reading forums and I'm still a bit lost. Thanks!

ReplyDelete